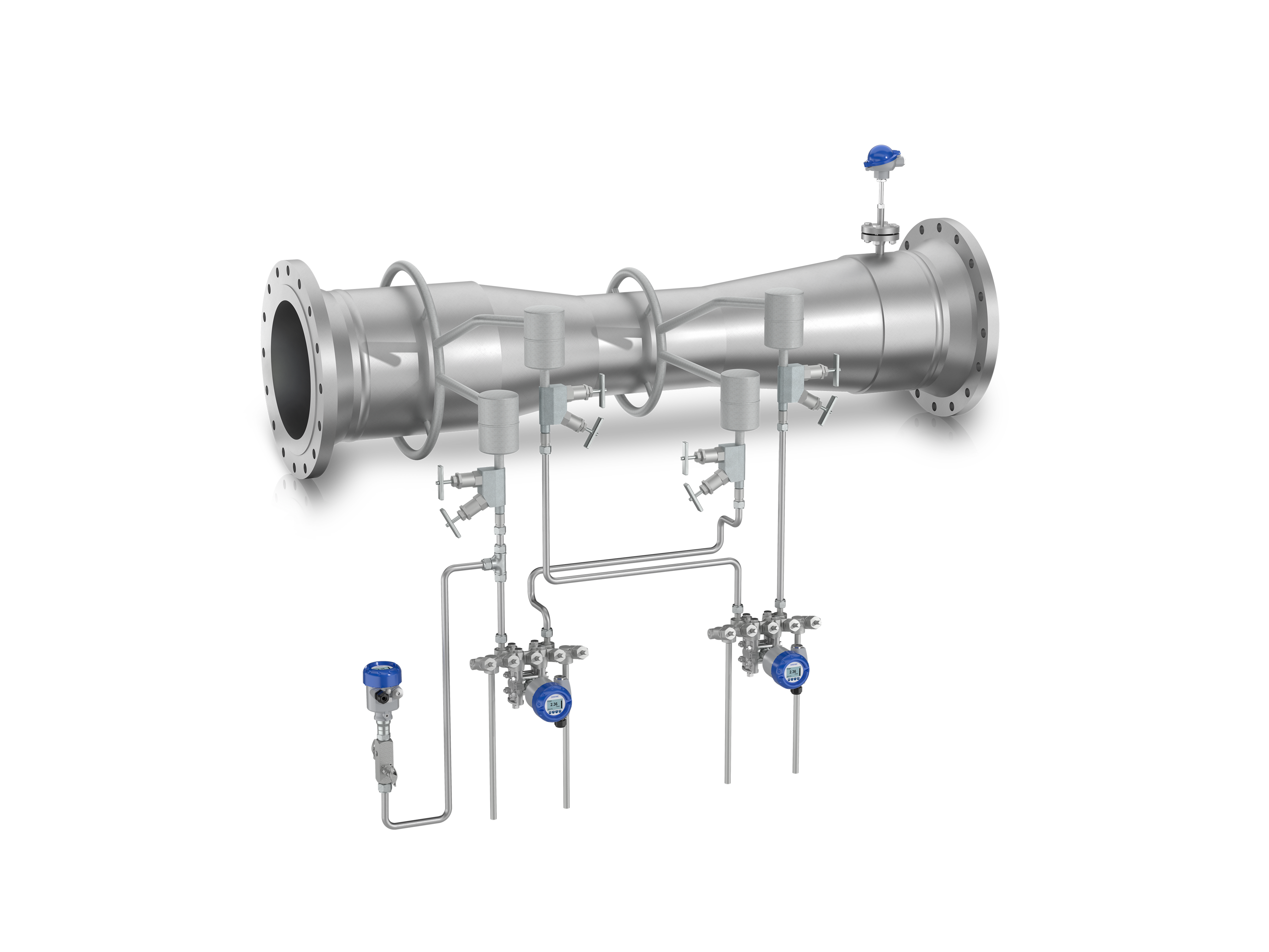

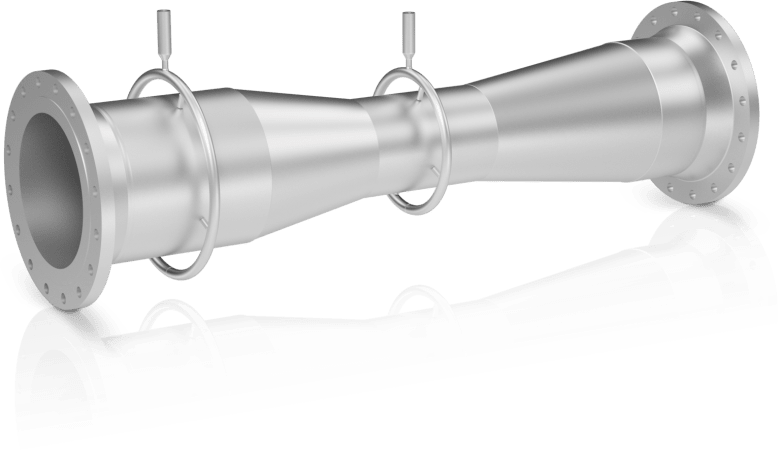

Venturi tube

Engineered primary element for DP flow measurement of liquids, gases and steam with the lowest residual pressure loss

- Machined or welded design (internally machined) according to EN ISO 5167, ASME MFC3

- Lowest residual pressure loss of all DP elements

- Only short inlet/outlet runs required

- From basic to special wet gas applications and high pressure conditions

Venturi tube

A Venturi tube is an engineered primary flow element for the most efficient and accurate differential pressure (DP) flow measurement. The typical Venturi shape with limited cone angles enable a pressure recovery of up to 95% of the generated DP. Together with optional annular chambers to balance deviation in the flow profile. With low maintenance requirements and a long life the Venturi tube offers a low total cost of ownership. A special Venturi tube that enables online measurement of additional process parameters such as steam wetness can also be provided.

Product highlights

- Typical uncalibrated uncertainty up to ±1.5%

- Optional accredited wet calibration at operating Reynolds numbers for uncertainties up to ±0.2%

- Typical pressure loss down to 5% of the generated differential pressure

- Low requirements for straight inlet and outlet runs

- Best option for large sizes and low pressure applications

- With weld ends or flange connections

- With optional annular chambers and multiple pressure taps

- Size: 2…48" (50…1200 mm) per standard, larger sizes upon request

- Low maintenance and long life with low total cost of ownership (TCO)

Typical applications

Power generation and other industries

- Steam and gas applications with high flow rates

- DP flow application with high accuracy requirements

- Performance testing

- Large line size applications

- Geothermal steam measurement

Related products

Download Center

Pressure instruments

Download Center

- Technical datasheets and handbooks

- Flyers and brochures

- Certificates and approvals

- Software and driver