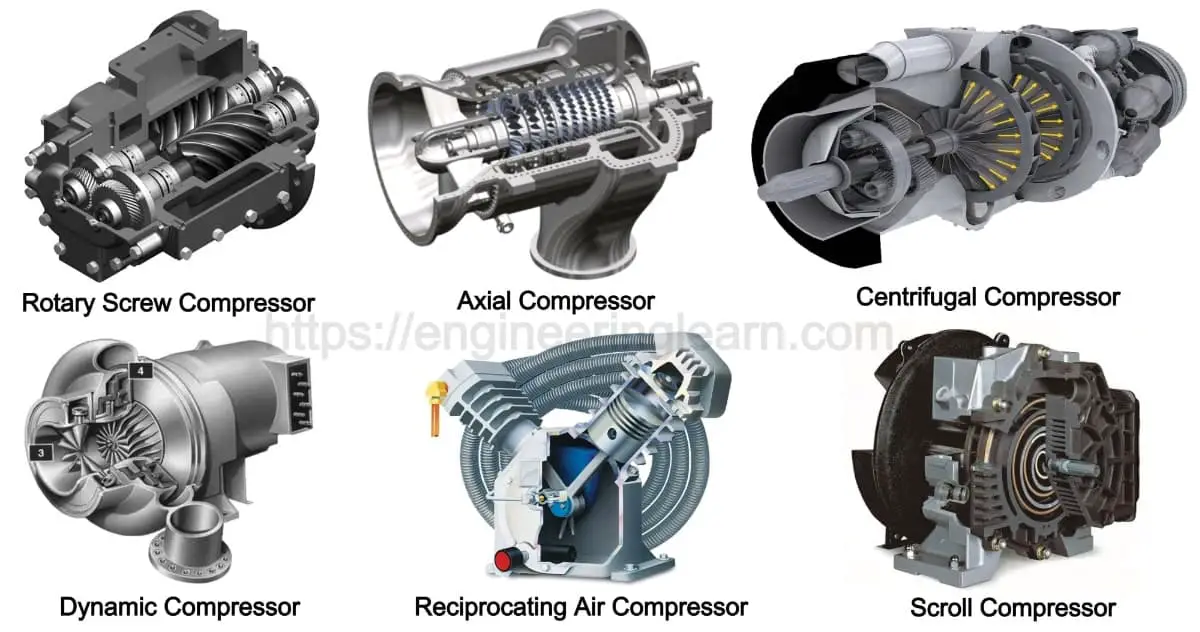

Introduction to Different Types of Compressors Used in Industry

Compressors are widely used in various industries to increase the pressure of a gas or vapor, allowing for efficient transportation, storage, and utilization of these substances. Different types of compressors are available, each suited for specific applications and operating conditions. Here's an introduction to some commonly used compressors in the industry:

Centrifugal Compressors Pdf Document

- Reciprocating Compressors: Reciprocating compressors use pistons driven by a crankshaft to compress the gas. They are commonly found in small-scale applications and have a wide range of applications, including pneumatic tools, refrigeration systems, and air conditioning units. Reciprocating compressors can deliver high-pressure outputs and are available in both lubricated and oil-free designs.

- Rotary Screw Compressors: Rotary screw compressors utilize two intermeshing helical screws to compress the gas. As the screws rotate, they reduce the volume, thus increasing the pressure. These compressors are widely used in industrial applications where a continuous and steady supply of compressed air is required. They are known for their high efficiency, compact design, and relatively low noise levels.

- Centrifugal Compressors: Centrifugal compressors use high-speed rotating impellers to accelerate the gas, converting kinetic energy into pressure energy. They are commonly used in applications that require large volumes of compressed air or gas at high pressures. Centrifugal compressors are known for their compactness, high flow rates, and suitability for continuous operation. They are often employed in petrochemical, power generation, and oil and gas industries.

Training Manual Of Compressor Pdf Document

- Axial Compressors: Axial compressors are primarily used in gas turbine engines and aircraft propulsion systems. They work on the principle of creating a continuous flow of gas by using a series of rotating and stationary blades. As the gas flows through the compressor, it undergoes multiple stages of compression, leading to a significant increase in pressure. Axial compressors are known for their high flow rates and are designed for applications that require large volumes of gas to be compressed.

- Scroll Compressors: Scroll compressors are commonly used in refrigeration and air conditioning systems. They utilize two interlocking spiral-shaped scrolls to compress the gas. One scroll remains stationary, while the other orbits around it, compressing the gas in the process. Scroll compressors are known for their compact size, quiet operation, and high efficiency. They are particularly suitable for applications that require a continuous supply of compressed gas or refrigerant.

For More Information Follow Mechanical Knowledge Factory

It's worth noting that each compressor type has its own advantages, limitations, and specific applications. The selection of a compressor depends on factors such as desired pressure ratio, flow rate requirements, gas properties, system efficiency, and cost considerations. It's crucial to carefully evaluate the requirements of a particular application to choose the most appropriate compressor type.

Sophomore | Industrial Design

10moInformative Thanks for sharing

ING in maintenance and specialized in Instrumentation

10movery well

Next Trend Realty LLC./ Har.com/Chester-Swanson/agent_cbswan

10moWell said.

Sales Associate at American Airlines

10moThank you for posting