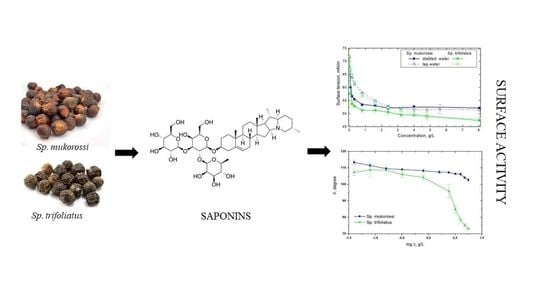

Surface Activity of Natural Surfactants Extracted from Sapindus mukorossi and Sapindus trifoliatus Soapnuts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Contact Angles Measurements

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Available online: https://www.alliedmarketresearch.com/surfactant-market (accessed on 26 October 2020).

- Edser, C. Latest market analysis. Focus Surfactants 2006, 5, 1–2. [Google Scholar] [CrossRef]

- Olkowska, E.; Rumanand, M.; Polkowska, Ż. Occurrence of Surface Active Agents in the Environment. J. Anal. Methods Chem. 2014, 769708. [Google Scholar] [CrossRef] [PubMed]

- Pradhan, A.; Bhattacharyya, A. Quest for an eco-friendly alternative surfactant: Surface and foam characteristics of natural surfactants. J. Clean. Prod. 2017, 150, 127–134. [Google Scholar] [CrossRef]

- Masakorala, K.; Turner, A.; Brown, M.T. Toxicity of Synthetic Surfactants to the Marine Macroalga, Ulva lactuca. Water Air Soil Pollut. 2011, 218, 283–291. [Google Scholar] [CrossRef]

- Rosen, M.J.; Li, F.; Morrall, S.W.; Versteeg, D.J. The Relationship between the interfacial properties of surfactants and their toxicity to aquatic organisms. Environ. Sci. Technol. 2001, 35, 954–959. [Google Scholar] [CrossRef]

- Cooper, A.; Kennedy, M.W. Biofoams and natural protein surfactants. Biophys. Chem. 2010, 151, 96–104. [Google Scholar] [CrossRef]

- Yang, C.-H.; Huang, Y.-C.; Chen, Y.-F.; Chang, M.-H. Foam Properties, Detergent Abilities and Long-term Preservative Efficacy of the Saponins from Sapindus mukorossi. J. Food Drug Anal. 2010, 18, 155–164. [Google Scholar] [CrossRef]

- Ghagi, R.; Satpute, S.K.; Chopade, B.A.; Banpurkar, A.G. Study of functional properties of Sapindus mukorossi as a potential bio-surfactant. Indian J. Sci. Technol. 2011, 4, 531–533. [Google Scholar] [CrossRef]

- Sachdev, D.P.; Cameotra, S.S. Biosurfactants in agriculture. Appl. Microbiol. Biotechnol. 2013, 97, 1005–1016. [Google Scholar] [CrossRef] [Green Version]

- Schmitt, C.; Grassl, B.; Lespes, G.; Desbrières, J.; Pellerin, V.; Reynaud, S.; Gigault, J.; Hackley, V.A. Saponins: A Renewable and Biodegradable Surfactant From Its Microwave-Assisted Extraction to the Synthesis of Monodisperse Lattices. Biomacromolecules 2014, 15, 856–862. [Google Scholar] [CrossRef]

- Muntaha, S.-T.; Khan, M.N. Natural surfactant extracted from Sapindus mukurossi as an eco-friendly alternate to synthetic surfactant e a dye surfactant interaction study. J. Clean. Prod. 2015, 93, 145–150. [Google Scholar] [CrossRef]

- Góral, J.; Wojciechowski, K. Surface activity and foaming properties of saponin-reach plants extracts. Adv. Colloid Interf. 2020, 279, 102145. [Google Scholar] [CrossRef] [PubMed]

- Ron, E.Z.; Rosenberg, E. Natural roles of biosurfactant. Environ. Microbiol. 2001, 3, 228–236. [Google Scholar] [CrossRef] [PubMed]

- Balakrishnan, S.; Varughese, S.; Deshpande, A.P. Micellar characterisation of saponin from Sapindus mukorossi. Tenside Surfactants Deterg. 2006, 43, 262–268. [Google Scholar] [CrossRef]

- Raja, M.; Suresh, M. Evaluation of Larvicidal Activity of Sapindus Emargintus (Family: Sapindaceae) Leaf Extracts against the Housefly Larvae (Musca domestica) LINN. Int. J. Sci. Res. 2015, 6, 200–204. [Google Scholar]

- Kommalpatti, R.R.; Valsaraj, K.T.; Constant, W.D.; Roy, D. Soil flushing using CGA suspensions generated from a plant-based surfactant. J. Hazard. Mater. 1998, 60, 73–87. [Google Scholar] [CrossRef]

- Ibrahim, M.; Khan, A.A.; Tiwari, S.K.; Habeeb, M.A.; Khaja, M.N.; Habibullah, C.M. Antimicrobial activity of Sapindus Mukorossi and Rheum emodi extracts against H. pylori: In vitro and in vivo studies. World J. Gastroenterol. 2004, 12, 7136–7142. [Google Scholar] [CrossRef]

- Vincken, J.-P.; Heng, L.; Groot, A.; Gruppen, H. Saponins, classification and occurence in the plant kongdom. Phytochemistry 2007, 68, 275–297. [Google Scholar] [CrossRef]

- Li, R.; Wu, Z.L.; Wang, Y.J.; Li, L.L. Separation of total saponins from the pericarp of Sapindus mukorossi Gaerten by foam fractionation. Ind. Crop. Prod. 2013, 51, 163–170. [Google Scholar] [CrossRef]

- Santini, E.; Jarek, E.; Ravera, F.; Liggieri, L.; Warszynski, P.; Krzan, M. Surface properties and foamability of saponin and saponin-chitosan systems. Colloid Surf. B 2019, 181, 198–206. [Google Scholar] [CrossRef]

- Hong, K.; Tokunaga, S.; Kajiuchi, T. Evaluation of remediation process with plant-derived iosurfactant for recovery of heavy metals from contaminated soils. Chemosphere 2002, 49, 379–387. [Google Scholar] [CrossRef]

- Grover, R.K.; Roy, A.D.; Roy, R.; Joshi, S.K.; Srivastava, V.; Arora, S.K. Complete 1H and 13C NMR assignments of six saponins from Sapindus trifoliatus. Magn. Reson. Chem. 2005, 43, 1072–1076. [Google Scholar] [CrossRef] [PubMed]

- Szymczyk, K.; Zdziennicka, A.; Krawczyk, J.; Jańczuk, B. Wettability, adhesion, adsorption and interface tension in the polymer/surfactant aqueous solution system. I. Critical surface tension of polymer wetting and its surface tension. Colloid Surf. A 2012, 402, 132–138. [Google Scholar] [CrossRef]

- Paria, S.; Biswal, N.R.; Chaudhuri, R.G. Surface Tension, Adsorption, and Wetting Behaviors of Natural Surfactants on a PTFE Surface. AIChE J. Soft Matter Synth. Process. Prod. 2015, 61, 655–663. [Google Scholar] [CrossRef]

- Rekiel, E.; Smułek, W.; Zdziennicka, A.; Kaczorek, E.; Jańczuk, B. Wetting properties of Saponaria officinalis saponins. Colloid Surf. A 2020, 584, 123980. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wojtoń, P.; Szaniawska, M.; Hołysz, L.; Miller, R.; Szcześ, A. Surface Activity of Natural Surfactants Extracted from Sapindus mukorossi and Sapindus trifoliatus Soapnuts. Colloids Interfaces 2021, 5, 7. https://doi.org/10.3390/colloids5010007

Wojtoń P, Szaniawska M, Hołysz L, Miller R, Szcześ A. Surface Activity of Natural Surfactants Extracted from Sapindus mukorossi and Sapindus trifoliatus Soapnuts. Colloids and Interfaces. 2021; 5(1):7. https://doi.org/10.3390/colloids5010007

Chicago/Turabian StyleWojtoń, Patrycja, Magdalena Szaniawska, Lucyna Hołysz, Reinhard Miller, and Aleksandra Szcześ. 2021. "Surface Activity of Natural Surfactants Extracted from Sapindus mukorossi and Sapindus trifoliatus Soapnuts" Colloids and Interfaces 5, no. 1: 7. https://doi.org/10.3390/colloids5010007